Unmatched quartz glass quality assured by AI

Quartz glass, whether natural or synthetic, is an exceptional material widely utilized in industry and research for a variety of high-tech applications in IT, communications, medicine, and the environment, thanks to its high chemical purity. Heraeus Conamic and Heraeus Comvance, among the world's few manufacturers of this material, have implemented artificial intelligence to enhance defect detection and ensure unparalleled levels of purity.

The AI systems have been developed by specialists from Heraeus' Digital Hub in close collaboration with process engineering experts from Heraeus Comvance and Heraeus Conamic, the world's largest manufacturer of synthetic quartz glass for telecommunications and a leading provider of customized solutions for the semiconductor industry, among others. This collaboration represents a unique synergy between digital innovation and industry expertise.

Thanks to the in-house development by the Digital Hub, both operating companies are poised to implement automated quality control with AI for one production line and one quartz glass product each in the second half of 2023. This transformative step is a testament to Heraeus' commitment to leveraging cutting-edge technology for enhancing precision and efficiency in production processes.

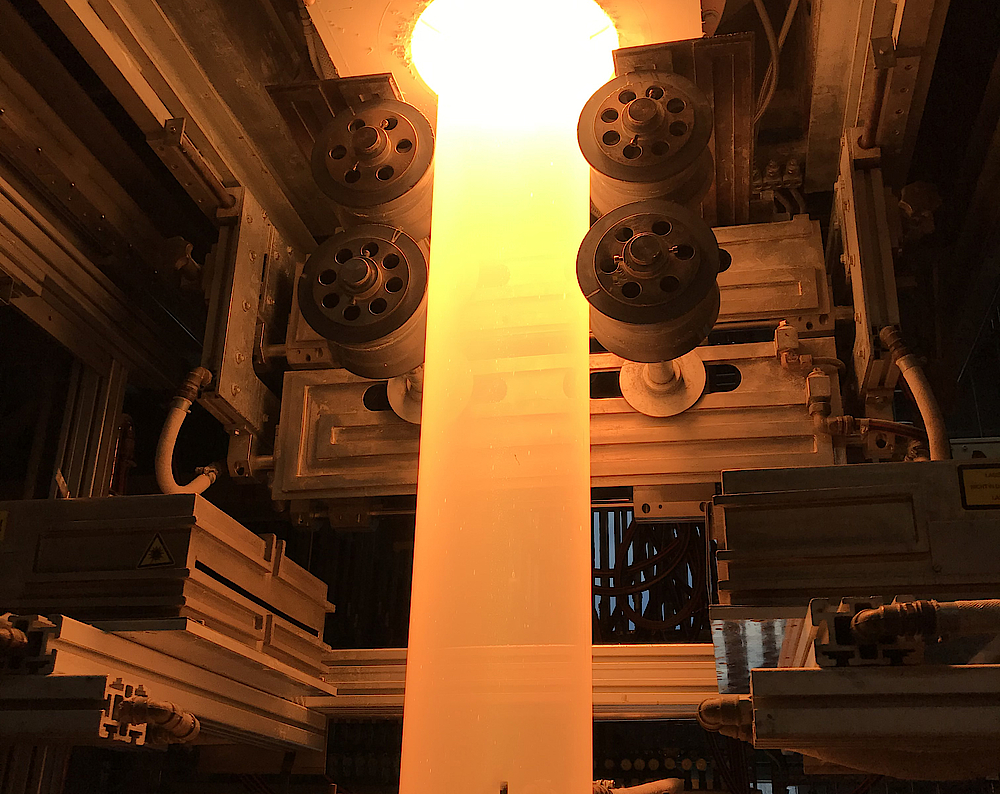

The AI systems will initially focus on detecting common defects in the quartz glass cylinders produced, such as larger bubbles and cracks, which have traditionally been identified through conventional image recognition or human inspection. The implementation of an AI measurement system, equipped with four cameras, is aimed at enabling independent identification, measurement, and comparison of different types of bubbles to ensure optimal quality for various applications.

By integrating AI into the quality control processes, Heraeus aims to elevate the level of accuracy and consistency, surpassing the limitations of conventional detection methods. This strategic initiative is expected to culminate in the gradual replacement of the existing quality control systems, signifying a significant leap forward in the pursuit of manufacturing excellence and customer satisfaction.

→ Find more information on this topic here.