Optimize the Material for your Application

Product Portfolio for Specialty Fiber Applications

There are a wide variety of applications for specialty optical fibers. For each of these applications a tailored fiber design is available for geometry, refractive index profile and transmission window. Heraeus can offer different solutions depending on your requirements.

Preforms

For fiber drawing we produce preforms for UV to infrared light applications with a numerical apertures up to 0.3 with configurable geometries including multiclad and shaped cores.

Tubes

The properties of the starting tubes used to jacket a core rod or used as a substrate for chemical vapor deposition influence the performance of the fiber. Key elements in the process are the material grade, purity, and geometrical precision of the tubes.

Rods

For fiber drawing of fibers with a pure silica core with a fluorinated polymer coating used to guide light from the pump laser to the active fiber cladding in medium-power laser systems.

Capillaries

Heraeus Covantics supplies capillaries for combining fibers in laser systems. Depending on your system configuration different material grades are available.

Pump Cladding

For active fiber fabrication of high power laser systems. A highly fluorinated silica layer is manufactured for the cladding where the pump light is guided in the active fiber. The maximum achievable numerical aperture is 0.3.

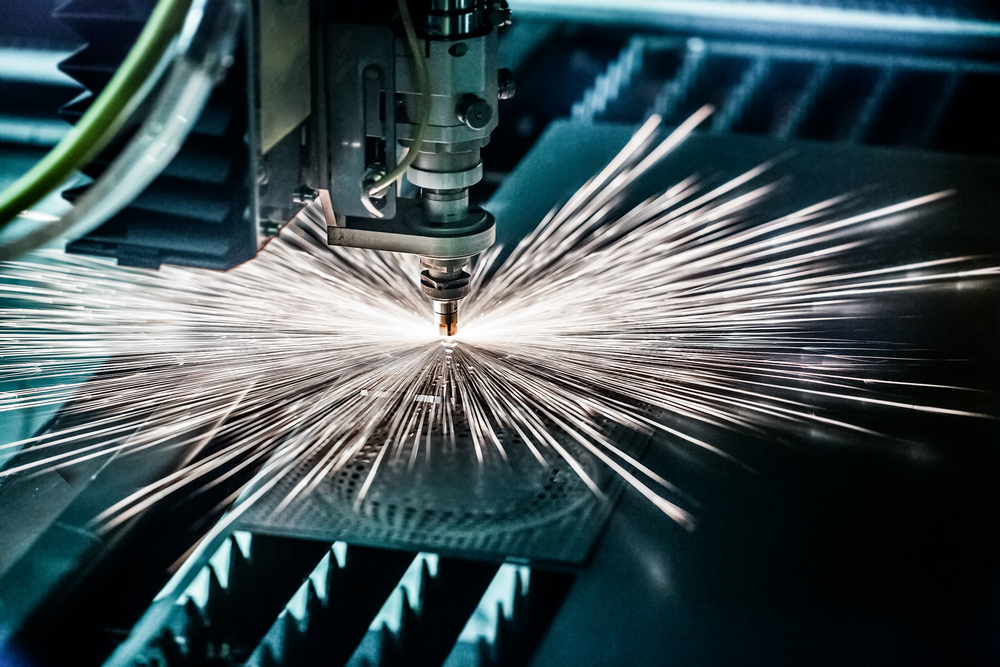

Plasma Deposition Service

We can apply our sophisticated Plasma Outside Deposition (POD) process on your own core rod.