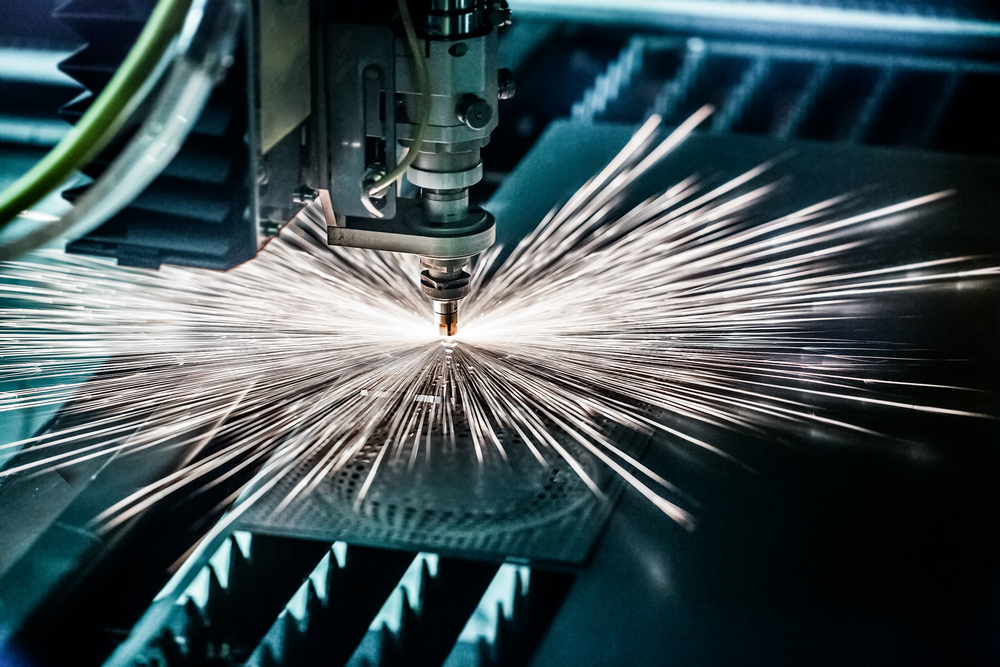

Laser Material Processing

For decades a growing number of industrial applications use lasers. While a CO2 laser was the standard for a long time, the need for free space optics and the limited spectral range were significant drawbacks that gave rise to other laser types, such as diode and fiber lasers.

The prime advantage of these lasers is their compactness and their availability of different wavelengths. Contrary to CO2 lasers, light of a shorter wavelength can be delivered to the working area using optical fused silica fibers. The focusing optics are made of fused silica as well.

Fused silica is the material of choice due to its low absorption (low loss) and high laser damage threshold enabling new applications like surface cleaning, structuring or even 3D printing. Heraeus offers a wide range of products tailored to the different applications.

Laser Pumping

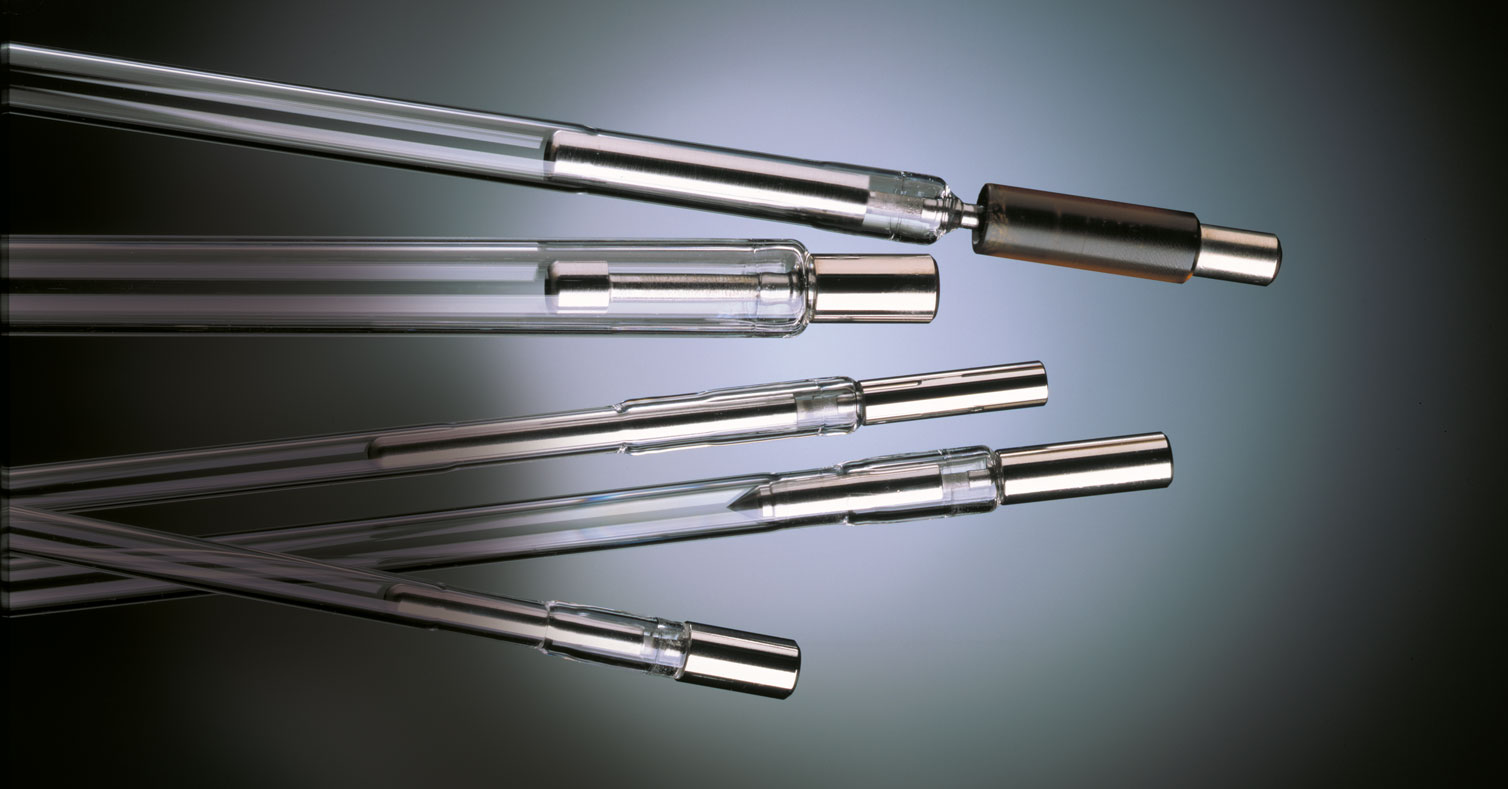

Laser Flash Lamps

In laser sources, laser beams are generated by pumping energy into the laser medium. There are several pumping methods for this. However, if special lamps are used, the basic options are CW (continuous wave) laser lamps or DC pulsed flash lamps.

Depending on the laser medium to be excited and the type of lamp to be used, Heraeus Covantics offers a wide range of customized solutions, e.g. undoped fused silica:

- Synthetic fused quartz (SFQ) - Suprasil 130

- Clear fused quartz (CFQ) - HLQ210, Heralux plus

- Doped quartz glass (Titanium doped quartz (TDQ)) - M235 plus

- Cerium doped quartz (CDQ) - M382 plus.

Common to all types of quartz glass are the consistently high levels of efficiency and stability - even with short and intense pulse rates and long lifetime requirements.

Pulsed flash lamps are used more and more often, even in non-laser applications, e.g. medical or cosmetic applications as IPL (Intense Pulse Lamps), or for sun simulation or semiconductor processing.

Fiber Lasers

Fiber lasers and fiber optic laser systems are a growing market for material processing and medical lasers. Many of these active fibers consist of an active core and a pump cladding. Depending on the power level and application, this pump cladding consists of undoped fused silica and a fluorine-containing polymer or a combination of undoped and highly fluorine-doped fused silica to guide the pump light in high-power lasers.

The pumping power can be further increased by using a non-circular shape of the pump cladding. For these applications, we offer tubes with round or asymmetric geometry and, if required, a customized highly fluorine doped fused silica layer.

Curing & Coating Processing

UV and IR industrial processes are long established in industry. High purity quartz glass is one of the key materials in the manufacture of related equipment, tools and modules. Its use translates to higher performing systems, and for end users – a lower cost of ownership (efficiency).

UV Curing

Since its inception 50 years ago, UV curing is prominently established in manufacturing processes – across various applications like printing, coating, and finishing steps. The UV curing process uses UV light to create a crosslink of polymers by a photochemical reaction. Even if UV LEDs generate UV light, especially in new systems, there are still a wide range of applications that use the high power of conventional UV lamps, e.g. medium pressure or metal halide lamps.

The Heraeus quartz glass fusion process is ideally designed to enable high-purity quartz tubes with excellent thermal stability to produce high-performance UV lamps, even when the lamps operate at the lamp limit. To further the application potential and efficiency, difficult to reach areas use UV light guides. It is possible to optimally target UV activations through customized UV fiber bundles (synthetic quartz glass).

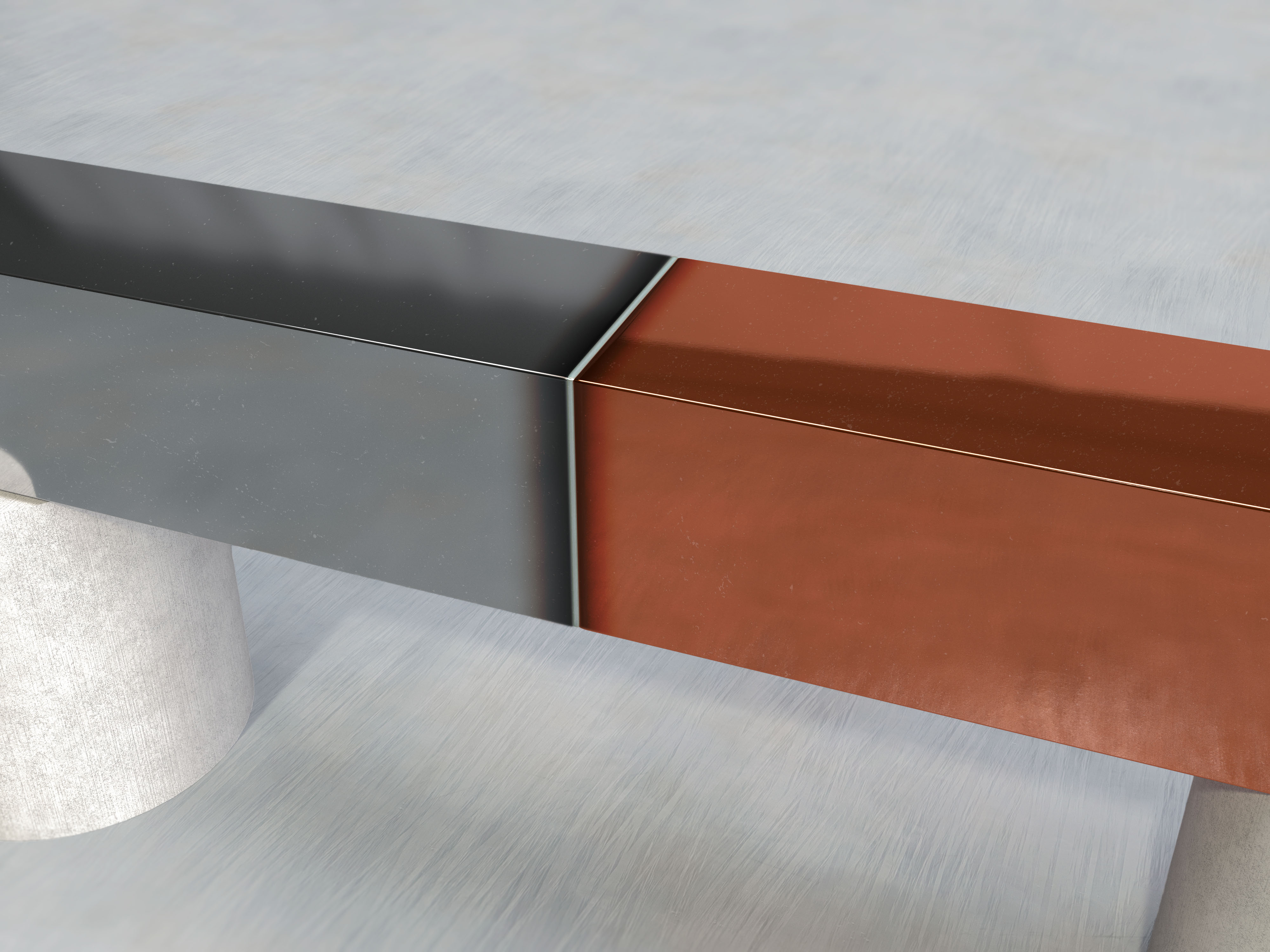

IR Coating

Industrial heating processes are common in manufacturing product and are an indispensable part of modern production processes. This brings value to many processes – drying or curing coatings, molding, joining or general thermal treatment.

Reliable, fast and powerful infrared emitters can only be designed with high-quality quartz glass, e.g. Heraeus quartz glass HLQ200.