Off-the-shelf Optical Components

For many applications, especially for prototypes or first articles standardized optical components, off-the-shelf products are used frequently. However, these may differ in quality from batch to batch. The specification of these products can be very lean (e.g.: specifying “fused silica”) to very tight and specific, stating either a transmission graph or even specific material grade.

New users may not be aware of all the different properties that are relevant to the performance of a system made of fused silica components. Others may not be aware of different grades of fused silica more suitable to a specific application.

Often, system designers must balance performance (optical performance as well it’s contribution to systems performance) with overall cost. This can be a complex task, especially considering the various properties that are specified for different fused silica grades. To help with the selection of the optimal material, it has proven beneficial to perform the following steps:

- Select the used wavelength region

- Define the principal optical function (light transmission or reflection)

- Consider additional requirements (absorption, inclusions, bubbles, fluorescence)

While many optical properties are available in commercially available simulation software, some other properties may be inquired at the supplier. Heraeus measures many properties and is a good source of information for detailed questions about its fused quartz and fused silica grades.

After the successful testing of a prototype, the optical design may be frozen or optimized for performance or cost. A task much easier, if the most relevant impact factors are known.

Optical Finisher and Workshop

An optics manufacturer faces many choices in his goal to deliver a good product as quickly as possible at the lowest cost. Many of these questions directly deal with the raw material:

- What is the right fused silica grade?

- What shape does the material come in?

How fast can the material be obtained?

Choosing the right material grade:

On first sight fused silica seems a simple material, but there are differences that can affect performance. It may involve transmission in a certain wavelength region, bubble or inclusion tolerance as well as tolerance on homogeneity of the refractive index resulting in distortions of wave fronts, to name just a few examples.

As can be expected, every grade comes at a different price. The technically best solution may not be price competitive. So finding the most suitable material for a given application is often done by experience. At Heraeus, we have gathered a lot of experience, that you can draw upon to make the right choice.

Why the shape of the material is important:

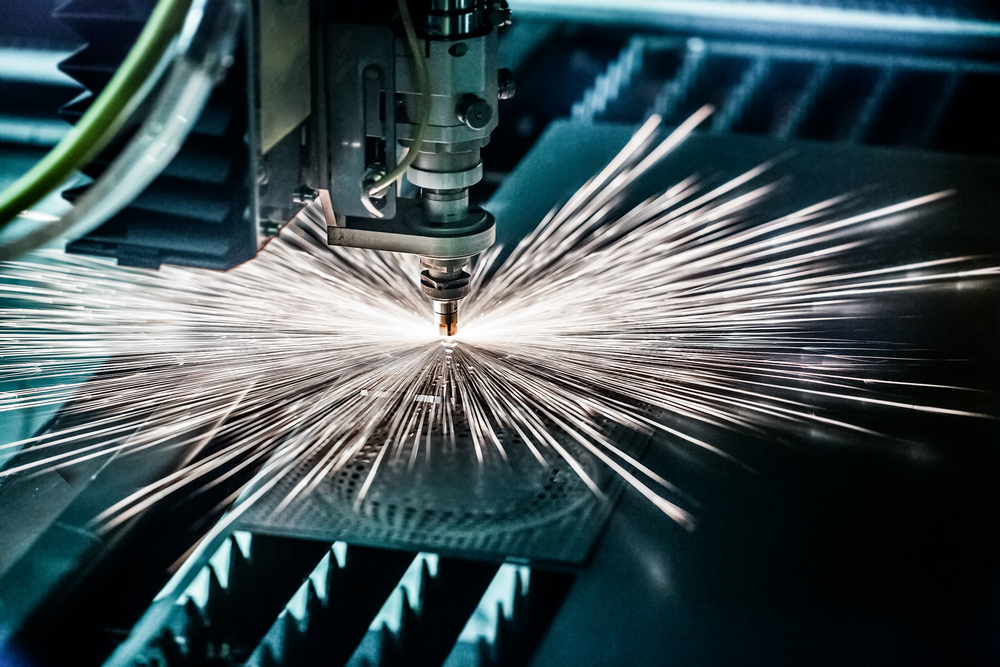

Many companies producing optical components have all the tools in house to process any shape of material into anything else. They can cut, core drill, machine, grind and polish. The possibilities for a production process are almost endless. It comes back to the questions of time, yield and cost.

In order to support a quick turnaround, we have developed a material grade that is supplied in near net shape; usually in rod form. We believe this reduces processing time and cost at the optical finisher so their customer gets the product as soon as possible. However, it is also possible to get our materials:

- Raw formed as a round or rectangular ingot

- Blanks as cut, ground or polished

Any unusual or special shape prepared by a C&C machine

Fast delivery:

Delivery time might be what sets you apart from competition. You may have a fast processing time, but not the right material on stock? Then drawing material form our shelves may be the solution to get material quickly.