From the first natural fused quartz tubes in 1976 to today’s synthetic fused silica materials, Heraeus Covantics has been an integral part in the production of optical fibers. These silica tubes are used as substrate material for the core deposition, cladding material for e.g. fiber lasers or redrawn into capillaries for e.g. fiber combiners.

Heraeus Covantics has continuously improved the quality and performance of our Fluosil® tubes serving the specialty fiber industry. We use proprietary processes that allow the production of fused silica tubes without the use of forming tools. These processes yield tubes of excellent purity and high geometrical precision.

Product Types & Benefits

High Purity Fused Silica Substrate and Cladding Tubes

- High purity synthetic fused silica quality

- F 300 material with less than 1 ppm OH

- Fluorine doped material types for refractive index and viscosity match are available

- For tight geometrical tolerance requirements Heraeus has engineered an enhanced tube production process (high precision = HP) to improve ovality and siding characteristics.

- The tubes are available in a wide range of sizes.

Pump Cladding for Laser Systems

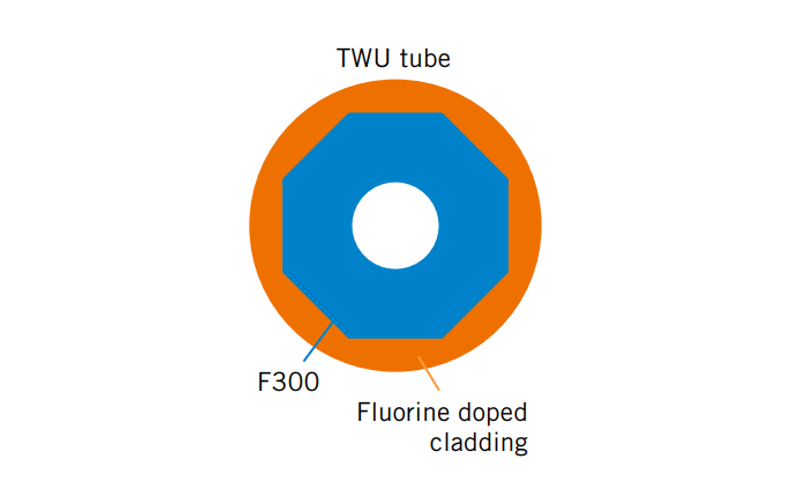

- Fluosil® tubes for pump claddings are characterized by the unique high fluorine concentration of the outer layer to guide the pump light.

- We offer a depressed index of refraction down to -26 x10-3.

- Patented design

- Shaped cross section to increase pump efficiency

Capillary Tubes

- Broad portfolio of high OH, low OH and fluorine doped materials available

- Tight tolerances

Fields of Applications

- Substrate Tubes:

Fluosil® synthetic fused silica substrate tubes are used in key steps of optical fiber production. Chemical Vapor deposition (CVD) processes rely on high purity and precise geometrical properties of the substrate tubes to achieve excellent core rods.

- Cladding Tubes:

Heraeus fused silica tubes can not only be used for the manufacturing of core rods in the deposition process, but also as cladding material, jacketing the core rod. Heraeus fused silica tubes can be tailored to customer specific requirements. Applying Fluosil® tubes as cladding material in the rod in tube process (RIT) benefits from the low hydroxyl content of our material. As a result, the interface between the core rod and cladding material stays free of hydroxyl ions.

- Pump Cladding for Laser Systems:

For high power lasers we offer tubes with an inner undoped section as pump cladding for the pump light and a highly fluorine doped fused silica layer to guide the light. The interface between pump area and guiding layer can be round but also shaped to increase the pump efficiency of the laser source. These kinds of tubes are commonly used for higher power lasers with increased power levels.

- Capillary Tubes:

Small diameter capillary tubes made of high purity synthetic fused silica or fluorine doped silica are used in the manufacturing of photonic crystal fibers or fiber combiners.