There are a wide variety of applications for specialty fibers. For each of these applications a tailored fiber design is required for geometry, refractive index steps and transmission window. With our Fluosil® preforms, Heraeus Covantics is able to offer different solutions depending on your requirements.

We can offer different core materials depending on the wavelength you want to use and can apply from single to multiple layers with different refractive index steps. Finally, we can adjust the shape of core and cladding to your requirements.

In addition, we offer our Plasma Outside Deposition (POD) process as service to coat your own core rod with a highly fluorine doped layer.

If you need assistance or guidance, please give us a call.

Product Benefits

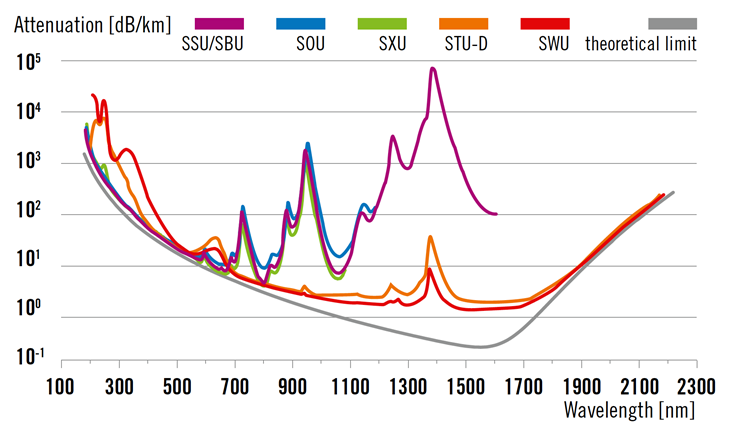

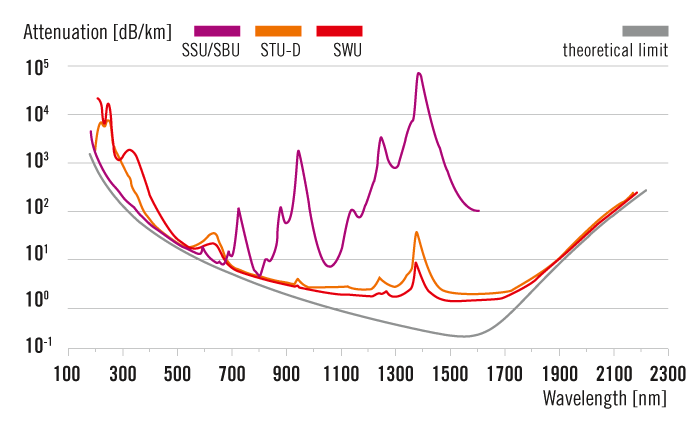

- High purity fused silica has a broad spectral transmission window, which makes it the material of choice for applications from the deep UV up to the infrared.

- Due to its high purity Fluosil® synthetic fused silica preforms have a superior laser damage threshold for material processing with high power lasers.

- Synthetic fused silica with highest purity is biocompatible and well suited for medical laser and minimal invasive surgeries.

Fields of Application

Minimally Invasive Surgeries

For medical treatments the most common wavelengths are given below with suitable preform types. For tight bend radii also high NA versions are available.

Preform Types

Therapy

Laser

Laser Color

Wavelength

Preform Type

Laser Coagulation

KrF

Dark Purple Laser

248 nm

SSU/SBU

Treatment of UV light sensitive skin diseases

XeCl

Purple Laser

308 nm

SXU

Dentistry

Ar+

Turquoise Laser

488 nm

SSU

Benigne Prostata Hyperplasie

NdYAG2F

Green Laser

532 nm

SSU

Photo Dynamic Therapy

HeNe

Red Laser

633 nm

SSU

Ophthalmology

NdYAG

IR Laser

1064 nm

SWU

Lithotripsy

HoYAG

IR Laser

2100 nm

SWU

Material Processing

Laser systems are used more and more commonly for material processing. Independent from the laser source in most cases an optical fiber is used to transmit the laser light from the system to the point of use. Depending on beam quality, spot size and additional required features of the final fiber we can realize your design. Even custom tailored in small quantities.

Wavelength Range

Preform Type*

UV (185-580 nm)

SSU/SSS

IR (700-2200 nm)

SWU/SWS

*SSU/SWU = single layer preform type / SSS/SWS = multi-layer preform type

Spectroscopic Applications

Optical fibers for spectroscopic applications need to transmit the light from the source and signals back without introducing additional absorption lines.

Preform Types

Transmission Range

Wavelength Associated

Preform Type

Broad spectral range

350 - 2200 nm

STU-D

Deep UV / UV-Radiation hard

185 - 580 nm

SBU

Infrared range

700 - 2200 nm

SWU

Resistance against y-radiation

185 - 580 nm

STU-D / SSU

UV Bundle Applications

For transmitting light in the deep UV range fused silica is the material of choice as it has a high resistance to UV radiation. It can be used for UV curing of adhesives or bundles for large homogenous spot sizes.

Webinar

Topic: Optical Fused Silica Large-Core Fibers - Influence of Design and Material on Fiber Performance

Downloads

Data Sheet: Specialty Fiber Preforms

Download